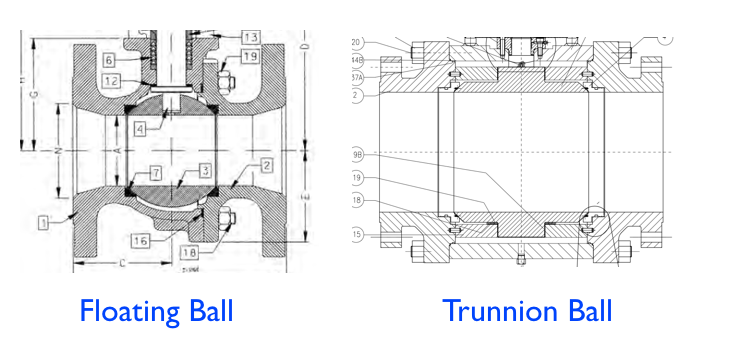

The name “floating” ball refers to the fact that the ball is suspended in the flowing medium held in position by the compression of the two elastomeric seats against it. The shaft is connected to a slot at the top of the ball which allows the ball to be driven travel through a quarter turn (90 degrees). The shaft allows for a certain amount of lateral movement of the ball that is generated from the upstream pressure acting against the ball. This small lateral movement in fact produces a load on the ball that presses it against the downstream seat. This type of ball valve design is therefore capable of bi-directional shut off.

As the nominal bore size of the ball increases, the weight of the ball also increases, and also the area subjected to the line pressure also increases. This has the overall effect of increasing the load (force) acting on the ball. There comes a point where it is no longer possible for the seats to support the ball and it is necessary to look at a different design: this where the trunnion mounted ball design comes into play.

As described above, there comes a point where owing to the high value of the loading forces on the ball it becomes no longer possible for the seats to support the ball and an alternative design is required.

The trunnion mounted ball design in effect addresses this problem where in effect the shaft, ball, and trunnion act as single assembly that supports the ball instead of the seats and the seats become “floating” in a kind of reversal of the “floating ball” design. Similarly, trunnion mounted ball design is also capable of bi-directional sealing.

An advantage of trunnion ball design over floating ball is the lower operating torque of the ball. This is particularly advantageous when the ball valve is actuated because it reduce the size of the actuator and hence the overall costs of the valve actuation package. Obviously this difference becomes important when the pressure class and valve increases.

Availability of Floating Ball Size/Pressure Class

Generally speaking for floating ball design, the higher the size required, the lower the pressure class it is available for the reasons described earlier in this post. For example the largest size available is 10″ @ ANSI #150; the largest size available for is 1″ @ ANSI #2500. Trunnion is available for all sizes and for all pressure classes.

Please feel free to browse our scope of supply for ball valves and contact us if you have a requirement: