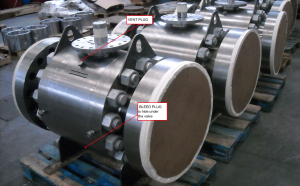

Double Block and Bleed Valves (DBB) are used in the process industries to provide double isolation for additional safety such that the upstream fluid does not reach the downstream plant equipment. The bleed and vent valves ensure that fluid is drained from the cavity between the seals and to drain any fluid downstream of the process stream.

DBB ball type valves use all the design features and benefits of trunnion mounted ball valves. The body is generally is manufactured from forged or bar stock material to ensure a high integrity pressure envelope for the valve body (housing).

Typical applications include manifold isolation, ring main isolation, instrumentation or process equipment isolation.

Size Range: 1″ thru’ to 24″ Full and Reduced Bore (DN25 thru’ to DN600) (larger sizes upon request)

Pressure Rating: ANSI #150 thru’ to ANSI #2500

Temperature Range: -196 degC to +500 degC

Seat Leakage: API6D, ISO 5208, API598

Materials of Construction: Carbon Steel, Stainless Steel, Duplex Stainless Steel, Higher Alloys available upon request.

End Connections: Flanged and BW ends

For further information or to discuss your enquiry, please contact us: