Plastic pipework is commonly used in many industrial applications in the chemical and pharmaceutical industry, waste incineration, and metal treatment for carrying exhaust or process gases. Whist the advantages of using plastic pipework including corrosion resistance , reduced weight, etc. does the carry the disadvantage that plastic pipework is potentially combustible, and in some instances, the potential for a small fire to spread rapidly through conflagration poses a potential hazard.

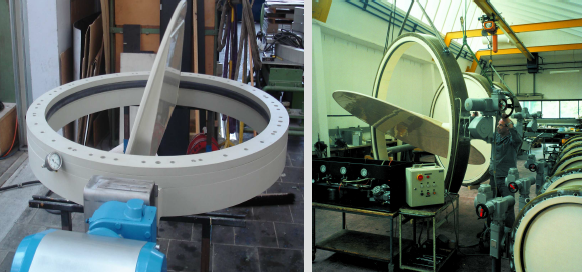

The use of strategically positioned fire protection dampers can help in preventing the spread of fire inside process pipework. The fire damper valves are constructed from chemical-resistant plastic together with a flame guard. The damper is triggered in the event that the temperature in the pipe rises.

These valves are manufactured in the following sizes: DN250 thro’ to DN3000 to suit specific applications.

Body and Disc

- Thermoplastic: PP, PE, PVDF

- Steel, Stainless Steel, and nickel based alloys.

- Fibre-Reinforced Plastic (FRP) e.g. Derakane Momentum

- Lining Material: E-CTFE, FEP, PFA, MFA

- Coating Material: E-CTFE, FEP, PEEK

Available in different gasket materials and flange end connections to international standards— DIN, ISO, ANSI, JIS etc.

Actuator

- Manual gearbox

- Electric actuator

- Pneumatic actuator

Body Configuration

- Flanged or clamped

To contact us with your enquiry, please send us an Email by clicking on the following link: