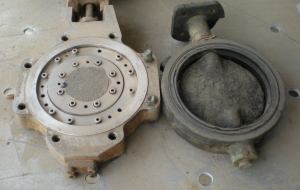

This photos shows two butterfly valves that were installed on the SAME pipeline for the SAME service. As you can see from the photo the valve on the right did not fair as well as the valve on the left. There are significant signs of damage to the valve disc and the liner. The client complained that the valve on the right was “passing”, in other words, it was not shutting off fully and was leaking. When it was removed from the pipeline for examination, it was clear from examination why this was happening…

This photos shows two butterfly valves that were installed on the SAME pipeline for the SAME service. As you can see from the photo the valve on the right did not fair as well as the valve on the left. There are significant signs of damage to the valve disc and the liner. The client complained that the valve on the right was “passing”, in other words, it was not shutting off fully and was leaking. When it was removed from the pipeline for examination, it was clear from examination why this was happening…

Why did the valve on the left perform better? This is because the valve was a triple offset butterfly valve designed for this type of “demanding” application on hydrocarbon service. It is a more robust design valve, constructed from the “correct” materials of construction for this service. Whereas a concentric rubber lined butterfly valve relies on an interference fit between the valve disc and liner, triple offset butterfly valves employ a robust metal-laminate seal installed on the valve disc that shuts off against a body seat. The triple offset geometry means that during the stroke there is no interference between the seal and seat increasing the service life of the valve. In addition triple offset valves are “fire-tested” and fully certified to comply with “fire-safe” valve standards such as API 607, API 6FA and other internationally-recognized Oil and Gas industry valve standards.

What is there to learn from this? Utility type valves, such as concentric rubber lined butterfly valves, are not designed for “demanding” oil and gas applications and in terms of technical performance are not in this league as triple offset butterfly valves.

Therefore correct valve selection is all important. In this example, the client was right to remove the valve from service and replace it with a more suitable valve.

For more information on triple offset butterfly valves, or to discuss your application, please contact us: