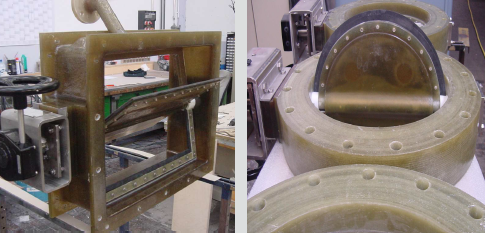

Thermoplastic butterfly valves for shut off, flow regulation, and diverting exhaust gases. These applications are low pressure applications, generally involving exhaust/flue gases where the flowing medium is both corrosive and/or hot. For these applications it is advantageous to use thermoplastic materials of construction as opposed to an exotic, high alloy metal. Because of the low operating pressure there are generally referred to as “damper” valves.

Thermoplastic butterfly valves for shut off, flow regulation, and diverting exhaust gases. These applications are low pressure applications, generally involving exhaust/flue gases where the flowing medium is both corrosive and/or hot. For these applications it is advantageous to use thermoplastic materials of construction as opposed to an exotic, high alloy metal. Because of the low operating pressure there are generally referred to as “damper” valves.

Example Applications

- Thermal power stations (gas turbine plants)

- DeNOx systems

- exhaust gas desulphurisation systems

- Metallurgical applications including metal foundries and precious/special metal processing

- Waste Air Purification Systems in Chemical and Pharmaceutical Industry

- Chemical Waste Incineration Plants

- Fire protection for plastic piping

The valves available in different versions depending on both the maximum operating temperature range and whether tight shut off is required. Below us a summary of available versions.

Available Options

- Applications with operating temperatures up to 100 degC (Type 1)

- Applications with operating temperatures up to 900 degC (Type 2a)

- Applications with operating temperatures up to 900 degC with tight sealing (Type 2b)

General Materials of Construction

- Body/Disc available in: thermoplastic, steel, stainless steel, and nickel-based alloy, glass fibre reinforced plastic;

- Liner: E-CETFE, FEP< MFA, PFA

- Gasket: EPDM, HYPALON, BUTYL, FPM, PTFE, or metallic materials

Thermoplastic (options)

- PE-HD

- PP-H

- PVDF

Glassfibre Reinforced (option)

- FRP Derakane 470

Composite (option)

- FRP, PFA

- FRP, FEP

- FRP, E-CTFE

Steel/Stainless Steel

- HII / P265GH

- 1.4404 / 1.4571

- 1.4876 / 1.4828

If you would like further information, or would like to send us your enquiry, then please contact us by clicking on the following link:

If you would like further information, or would like to send us your enquiry, then please contact us by clicking on the following link: